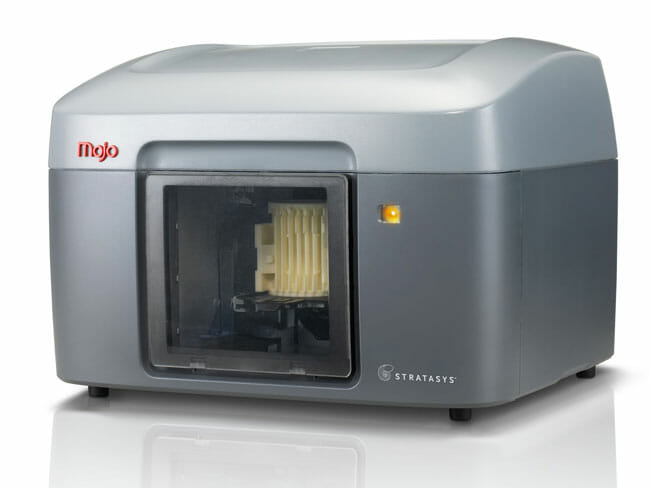

A futuristic new technology, the 3D printer, has been introduced to Columbus Academy’s science department. The printer is used by Mr. Devore’s Physics 2 class, who will participate in the First Technology Challenge, a competition where teams build robots to accomplish tasks.

The printer is easy to maintain and operate, allowing the class to design parts in a CAD (Computer Aided Design Software) system and send the files to the printer. The printer then builds the design by heating plastic cord and building from the base up. The class intends to use the printer to manufacture pulleys, since the competition does not allow them to purchase pulleys.

Although efficient and extremely useful, the 3D printer has several drawbacks. The items the printer can produce are limited. Devore explains that “the maximum size parts that can be produced are 5″ x 5″ x 5,” although this is not an issue for the class, as most parts they create do not exceed this size. In addition, the cost is a primary concern, as a 1 kg spool of plastic costs $30 on average. The high cost may raise disputes about the school funding the printer, but it has confirmed its worth in science classes and may be useful in other subjects like geometry, where it could be used to print out models of shapes, or history, where students could design and print models of ancient buildings.

Outside of Academy, 3D printer technology continues to develop, generating both excitement and concern. 3D printers have the ability to create working guns, and as the printers become more common, people will be able to easily manufacture their own weaponry. In the present, however, the printers are proving to be beneficial; and as President Obama stated in his most recent State of the Union address, these printers could be the future of modern manufacturing.

Written by Josh Levy’15